End Suction Vortex Pumps Designed for a Wide Range of Agricultural Fertilizer Mixing Industry Applications

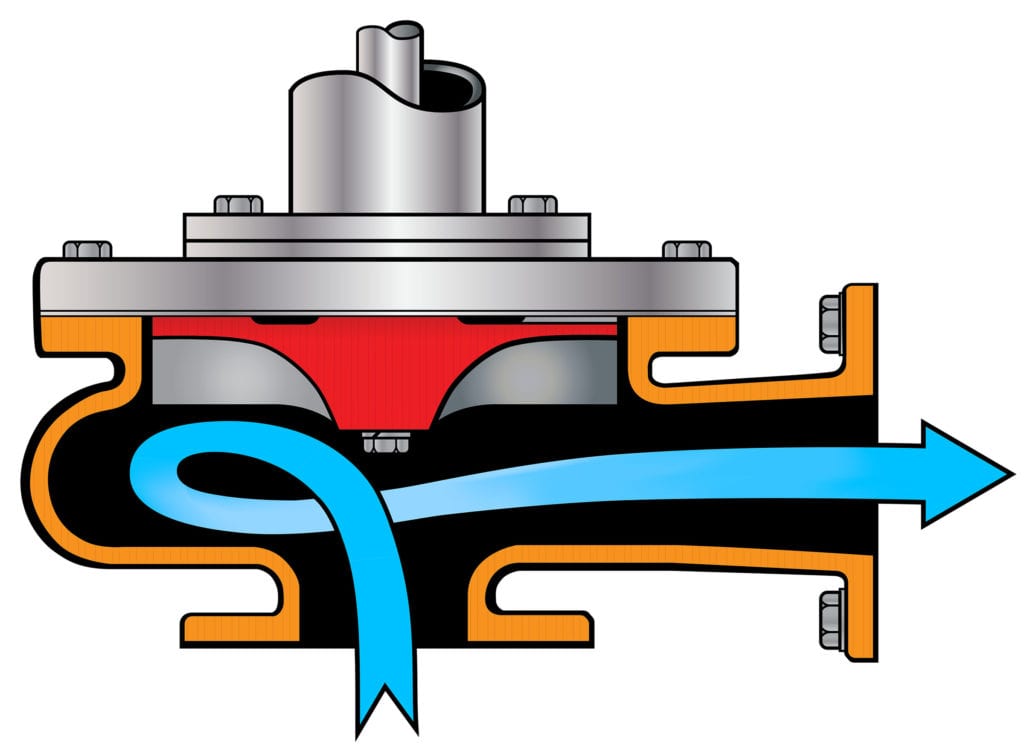

Vertiflo Pump Company’s Series 1500-1600 Series horizontal end suction vortex pumps have a wide range of agricultural mixing pump applications for fertilizers. Fully recessed design which accommodates passage of solids. All impellers have wiping vanes which reduce axial loading and prevent dirt from entering the sealing area. Impeller is keyed to shaft, and an impeller locking screw assures positive attachment. Vortex Design provides an unrestricted flow since the impeller is not normally in contact with the solids being pumped.

Capacities to 1600 GPM, heads to 170 feet TDH, temperature to 250 degrees Fahrenheit, fully recessed vortex impeller, with packing or mechanical seal. Pumps are designed with back pull-out construction that permits easy inspection and access for service or maintenance — if it is ever needed — without disturbing the piping to the pump. Standard construction is Cast Iron, 316 Stainless Steel fitted, all 316 Stainless Steel, Alloy 20 or CD4MCu.

The base-mounted Series 1500 pumps are designed for use with any T frame motor or with virtually any type of drive. Rugged heavy duty cast iron design incorporating integrally cast support and ribbed mounting feet which assure a solid, dependable pump installation and operation. One frame fits all pump sizes. External impeller adjustment is standard. Grease lubrication of bearings is standard; oil lubrication available. Packing or various mechanical seal arrangements are available as standard options of this pump. Shaft is 416 stainless steel, precision machined with preferred taper at impeller location. Positive attachment is provided with castellated impeller nut and cotter pin, which assures that the impeller will not back off the shaft if the pump is accidentally operated in reverse rotation. 316 stainless steel shaft is optional. Every power frame contains an external impeller adjustment utilizing jackscrews which provides for clearance adjustment of the impeller. This adjustment feature compensates for internal wear. Expensive casing and impeller wearing rings are eliminated.

Series 1600 horizontal close-coupled end suction pumps are designed for use with any NEMA Standard JP Shaft Motor. VERTIFLO’s close-coupled pumps are designed with back pull-out feature. NEMA standard JP shaft extension allows for easy interchangeability to packing, standard mechanical seal or optional single or double mechanical seals of various designs and materials of construction. Shaft construction of 316 stainless steel is standard. It is positively driven and gasketed, protecting motor shaft from liquid being pumped.

Industry News from the Hydraulic Institute

A Complete Line of Pumps for Industry

Vertiflo Pump Company’s Vertical Sump Centrifugal Pumps, Horizontal End Suction Centrifugal Pumps and self-priming pumps are delivered fast, usually in half the typical lead time. Vertiflo’s vertical sump pump line offers up to 3000 GPM, 250′ Heads and 26′ depth. The horizontal end suction pump line offers up to 3000 GPM and 300’ Heads.

Vertiflo pumps are designed for nonresidential applications and currently over 20,000 are operating successfully worldwide. Vertiflo is recognized as a quality manufacturer of dependable pumps, and continues to grow and encompass new applications in the pump industry.