Determine how booster and suction lift applications are used.

Originally published in the February 2019 issue of Pumps & Systems by Justin McDaniel

Irrigation pump requirements are influenced by the type and scope of the system to be installed. Gathering some basic information from the irrigation plan is essential when selecting the correct pump for the application.

Specific site requirements may also influence pump selection. If the site has a limited window when watering can occur, the pumping system must be sized to deliver all of the water required during that window. An undersized pump prevents the system from meeting the total irrigation requirements during the hottest periods.

Additionally, the type of sprinkler selected and the location for the pump can have a material impact on the cost of the pumping equipment and long-term system operating costs. In general, pump selection is governed by four factors:

1 Required operating pressure. Gather the operating pressure requirements from the irrigation plan, noting the required maximum pressure.

2 System flow. It is important to understand the scope of the system.

3 Friction losses. Calculate the total head loss and elevation change from the outlet of the pump to the highest sprinkler head, as well as the suction lift head requirements.

4 Budget. The design of an irrigation system, as well as the site characteristics, can have dramatic ramifications for the cost of the pump. The available power supply is always an important factor to consider and may also impact the cost of the pump.

Common Irrigation Pumps

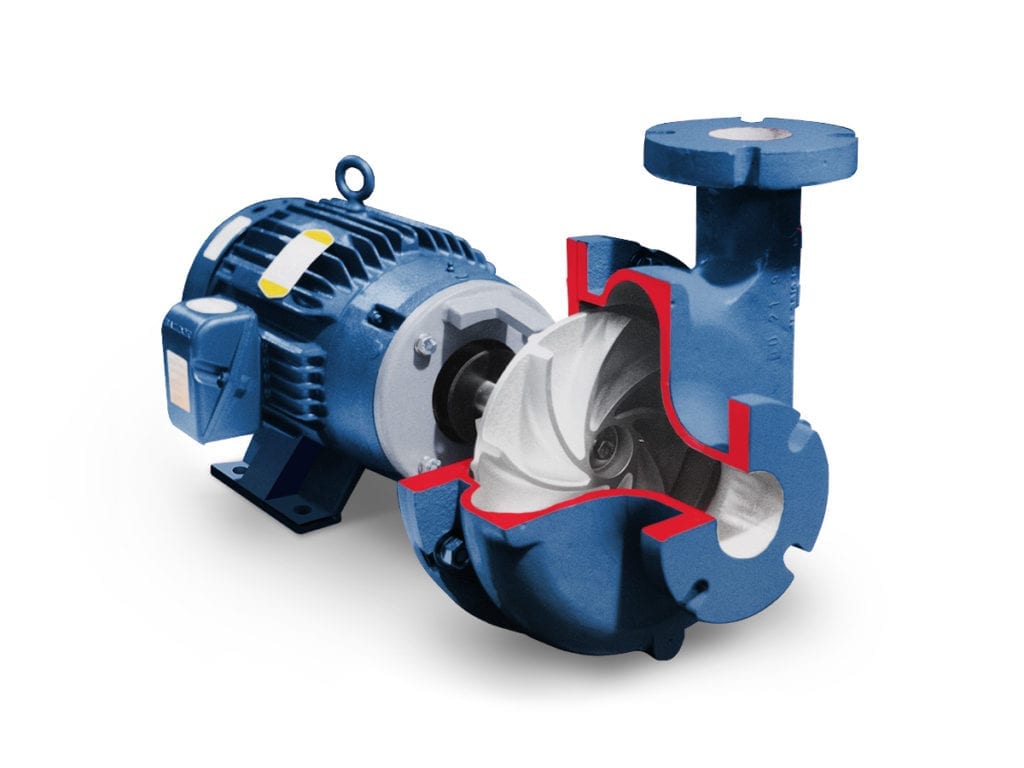

There are two main actions that a pump performs in an irrigation application: pressure boost or suction lift. The four styles of pumps that are typically used for these applications:

- horizontal centrifugal

- submersible

- vertical turbines

- vertical multistage pumps

Boost Applications

Booster pumps are used to increase (boost) the water pressure in the system. Primarily, booster pumps are used on domestic or municipal water systems when the existing pressure is not adequate for the irrigation system.

The two most widely used are horizontal centrifugal and vertical multistage. The selection of the pump depends on three factors:

- pressure is required to run the system

- what type of efficiency must be reached

- the type of water: municipal, reclaimed water or gravity supply tanks

Vertical multistage pumps are designed to handle clean water that is free from large solids and debris. Vertical multistage pumps lend themselves to higher pressures, whereas horizontal centrifugal pumps lend themselves to a lower maximum pressure range but are generally more forgiving when handling dirty water.

Horizontal centrifugal pumps and vertical turbines can handle dirty water as long as a screen is present. The screen is important because, without it, the irrigation system can get plugged up. Submersibles and vertical multistage pumps are recommended for boosting clean water. Solids or debris can damage these without the use of components such as filters.

Suction Lift Applications

In a suction lift application, the system does not have incoming pressure but is instead pulling from a water source, such as a lake, river, sump, etc. Suction lift applications commonly require the use of horizontal centrifugal pumps and vertical turbines. An advantage of horizontal centrifugal pumps is that they are easier to install and maintain because the internal parts are easily accessible. Vertical turbines and submersibles are suited to suction lift applications since they are located in the water and do not need to create the vacuum to lift water to the pump intake.

Variable Frequency Drives & Irrigation Systems

VFDs are not required for smaller irrigation systems with nonvarying flows. They are recommended for larger systems to enable soft starts and energy reduction.

Click the link for the full article in Pumps & Systems magazine February 2019.

Industry News from the Pumps & Systems

A Complete Line of Pumps for Industry

Vertiflo Pump Company’s Vertical Sump Centrifugal Pumps, Horizontal End Suction Centrifugal Pumps and self-priming pumps are delivered fast, usually in half the typical lead time. Vertiflo’s vertical sump pump line offers up to 3000 GPM, 250′ Heads and 26′ depth. The horizontal end suction pump line offers up to 3000 GPM and 300’ Heads.

Vertiflo pumps are designed for nonresidential applications and currently over 20,000 are operating successfully worldwide. Vertiflo is recognized as a quality manufacturer of dependable pumps, and continues to grow and encompass new applications in the pump industry.